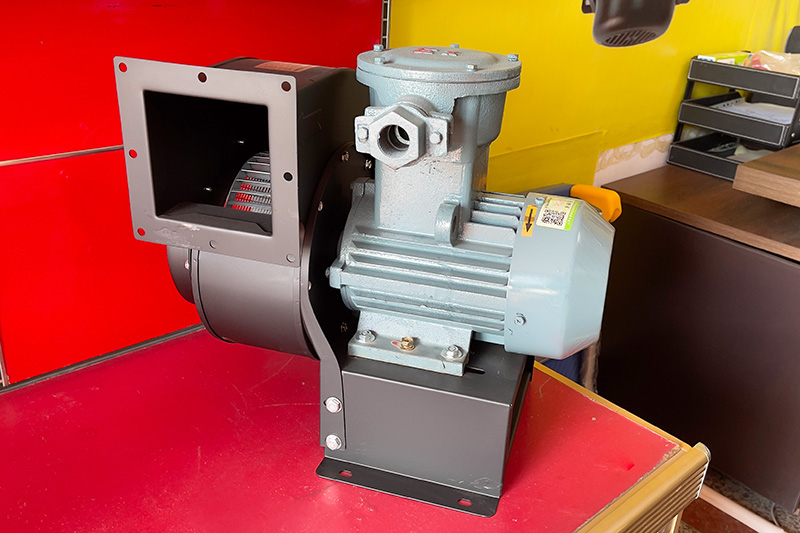

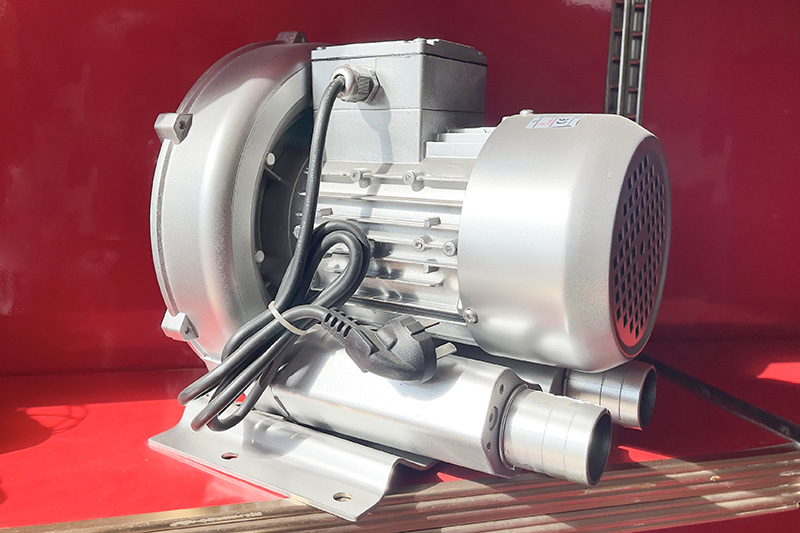

The application area of fast centrifugal fans is more common, not only in industrial production, but also in people's lives. In fact, this is due to the fact that fast centrifugal fans have many advantages, such as easy installation, ease of use, and simple maintenance. Then, in the specific application process, what factors will directly affect its work effectiveness? In response to this problem, everyone should first understand that the fast centrifugal fan you are referring to is also a product that belongs to the centrifugal fan product. The reason why this product can obtain a high operating rate is that its centrifugal impeller is different from the centrifugal impeller used in general machinery and equipment. Naturally, the high efficiency of the centrifugal fan is closely related to the speed ratio of the centrifugal fan, but it does not mean that the speed ratio is fast, which means high efficiency.

Centrifugal impellers are often selected because this component has a certain practical effect of energy saving and environmental protection. It can not only ensure that the machinery and equipment are in a high group and high efficiency, but also save a part of the electromagnetic energy. The use of electromagnetic energy convenience is particularly effective. Generally speaking, we can improve the working efficiency of the fast centrifugal fan according to two levels, respectively: 1. Adjust the aperture size of the centrifugal impeller; 2. Effectively set the deflection level of the centrifugal impeller.

Generally speaking, when the diameter of the centrifugal impeller becomes larger, it is likely to represent that the specifications of such products are also very large. Therefore, the output power has also increased to a certain extent, which also shows that the volume of the centrifugal fan with excessive output power will be slightly larger. Also, if the skew level is very small, then its output power is likely to be very small as well. On the contrary, it indicates that the output power will increase. However, this is also limited, usually maintained within an obtuse angle, otherwise it is likely to directly affect its service life.