The centrifugal fan is a machine that relies on the input mechanical energy to increase the gas pressure and discharge the gas. It is a driven fluid machine. Centrifugal fans are widely used in ventilation, dust removal and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings; ventilation and induced draft in boilers and industrial furnaces; cooling and in air conditioning equipment and household appliances. Ventilation; drying and selection of grain; air source of wind tunnel and inflation and propulsion of hovercraft, etc.

working principle

According to the principle of converting kinetic energy into potential energy, a high-speed rotating impeller is used to accelerate the gas, and then decelerate and change the flow direction to convert kinetic energy into potential energy (pressure). In a single-stage centrifugal fan, the gas enters the impeller from the axial direction, changes to the radial direction as the gas flows through the impeller, and then enters the diffuser. In the diffuser, the gas changes the direction of flow and the increase in the cross-sectional area of the duct slows down the gas flow, which converts kinetic energy into pressure energy. The pressure increase occurs mainly in the impeller, and secondly in the diffusion process. In a multi-stage centrifugal fan, a recirculator is used to move the airflow to the next impeller, creating a higher pressure.

What are the functions?

The working principle is basically the same as that of the turbo compressor. It is because the gas flow rate is low and the pressure change is not large. Generally, the change of the specific volume of the gas does not need to be considered, that is, the gas is treated as an incompressible fluid. Centrifugal fans can be made into two types: right-handed and left-handed. Viewed from the side of the motor: the impeller rotates clockwise, which is called a right-handed fan; the impeller rotates counterclockwise, which is called a left-handed fan.

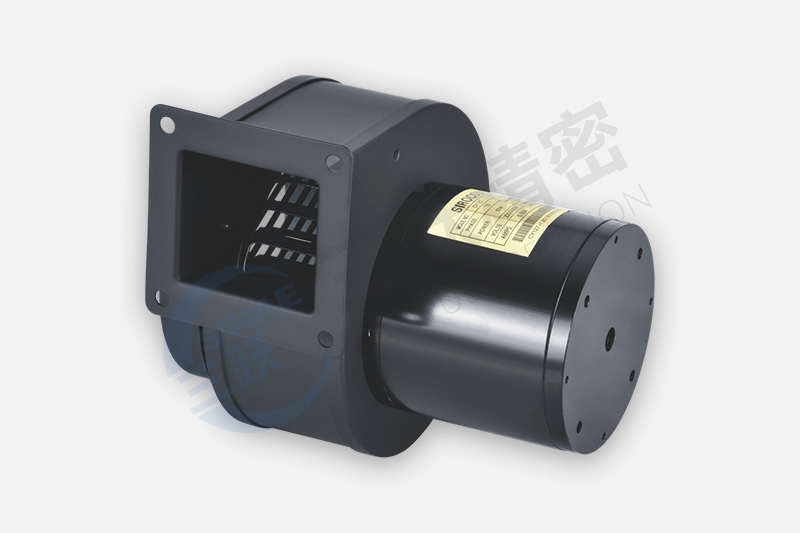

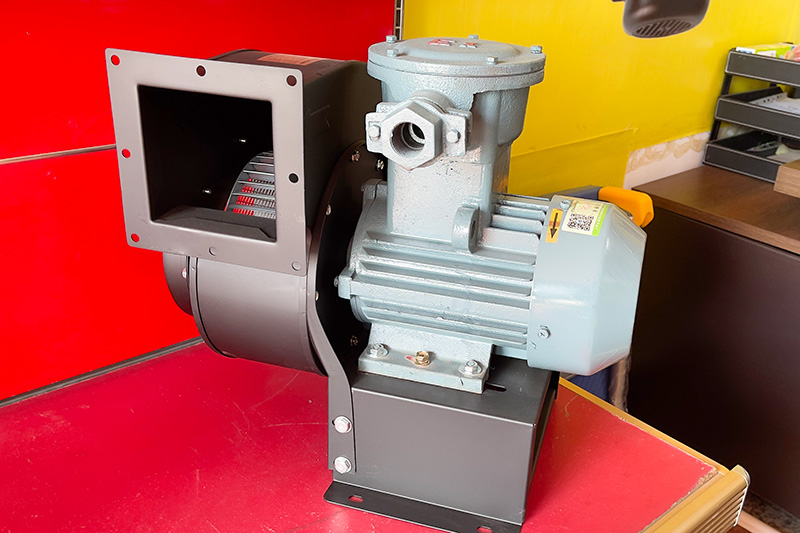

structure

It is composed of casing, main shaft, impeller, bearing transmission mechanism and motor.

Chassis: It is made of steel plate, which is strong and reliable. It can be divided into integral type and semi-open type, and the semi-open type is convenient for maintenance.

Impeller: consists of blades, curved front disc and flat back disc.

Rotor: Static balance and dynamic balance should be done to ensure smooth rotation and good performance.

Transmission part: It consists of main shaft, bearing box, rolling bearing and pulley (or coupling).