Adjustment mode:

During the operation of the centrifugal fan, the actual resistance of the system inevitably deviates from the theoretical resistance, so it is necessary to adjust the working point of the centrifugal fan to meet the actual resistance requirements of the system. The adjustment mode of the centrifugal fan generally includes the adjustment of the inlet baffle and the adjustment of the speed. The resistance loss caused by the adjustment of the inlet baffle is relatively large, which easily leads to low efficiency of the centrifugal fan. Adjusting the speed of the fan through the frequency conversion motor or permanent magnet motor can adjust the air volume of the fan, which is more suitable for the pipe network system and achieves the effect of reducing the energy consumption of the centrifugal fan.

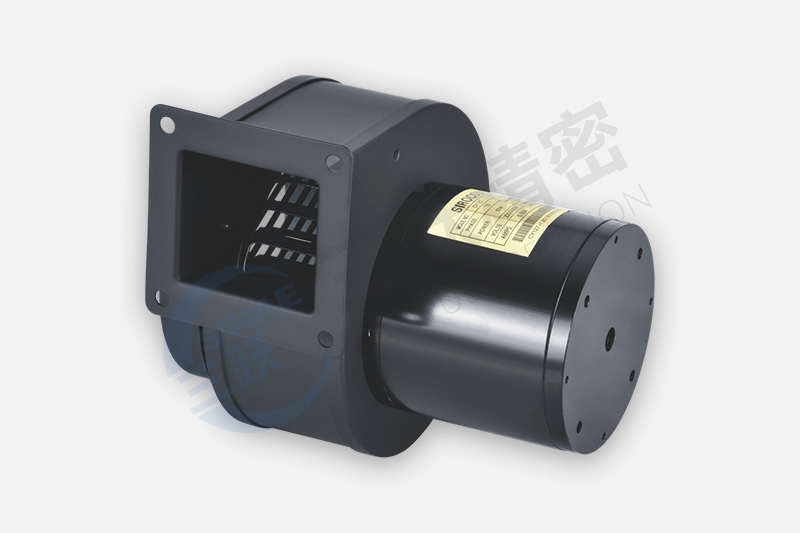

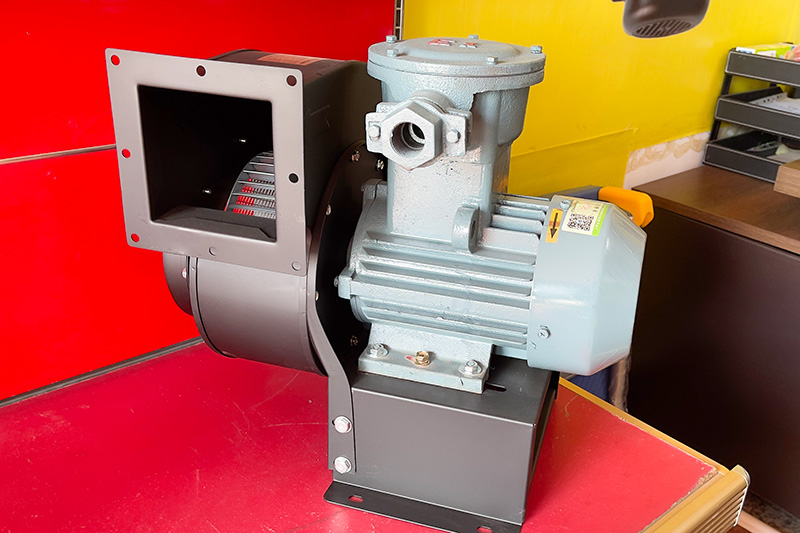

Fan model:

The efficient optimization of the fan model is one of the important reasons for improving the efficiency of industrial centrifugal fans. The impeller cover and blade type line are very important to the efficiency of the centrifugal fan, and the reasonable and efficient blade type will affect the efficiency of the centrifugal fan. By adjusting the blade inlet and outlet angles, optimizing the wheel cover line, optimizing the inlet flow path, and improving the efficiency of the centrifugal fan. Dongguan Sanyue Precision Electromechanical Co., Ltd. is a technology-based enterprise specializing in the production of various specifications of high-temperature centrifugal fans (long-axis motors), high-temperature motors and other series of pneumatic products that integrate R&D, production, sales and service. The products have passed CE \FCC\ROHS and other certifications, contact number: 0769-88811878.

suitability:

Centrifugal fans work in the system, and the air volume and air pressure do not match the system, which will lead to low fan operation efficiency. Advanced CFD can be used in simulation technology to select high-efficiency fans with operating efficiency points that better match system performance, so that the high-efficiency operating area of the fans can match the pipe network system, making the transformed centrifugal fans more efficient.

Pipe network optimization:

If the configured pipe network is not suitable, the industrial centrifugal fan will reduce the operating efficiency due to the increase of resistance, resulting in increased energy consumption. The pipe network design should be reasonable to avoid spoilers. In order to reduce the air flow spoiler in the inlet and outlet pipes of the centrifugal fan, the inlet and outlet pipes of the centrifugal fan should be designed as reasonably as possible to reduce bending and diameter, so as to improve the operating efficiency of the centrifugal fan.