High-temperature fans are special fans, specially used in high-temperature workplaces. High-temperature fans have high temperature resistance and high-pressure resistance. The types mainly include: stainless steel high-temperature fans, transmission high-temperature fans, centrifugal high-temperature fans, etc. High-temperature fans are widely used Used in chemical industry, petroleum, metallurgy, forging, electric power, nuclear power, environmental protection and other fields.

Features

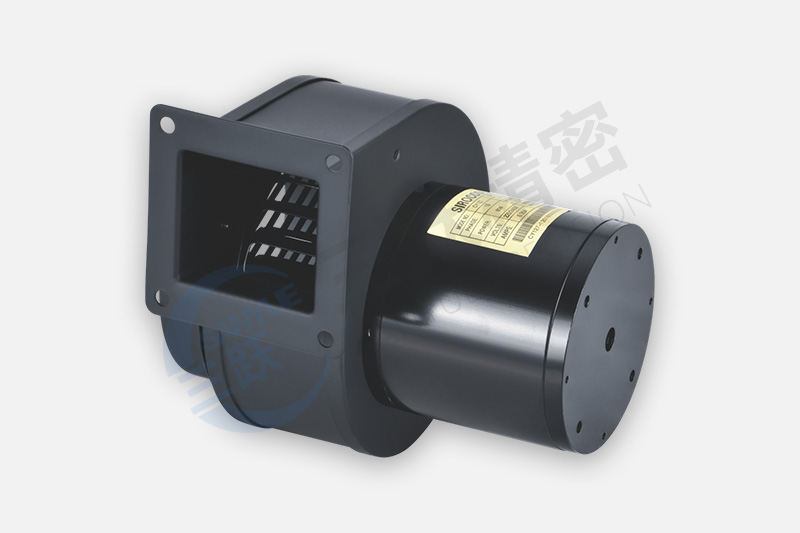

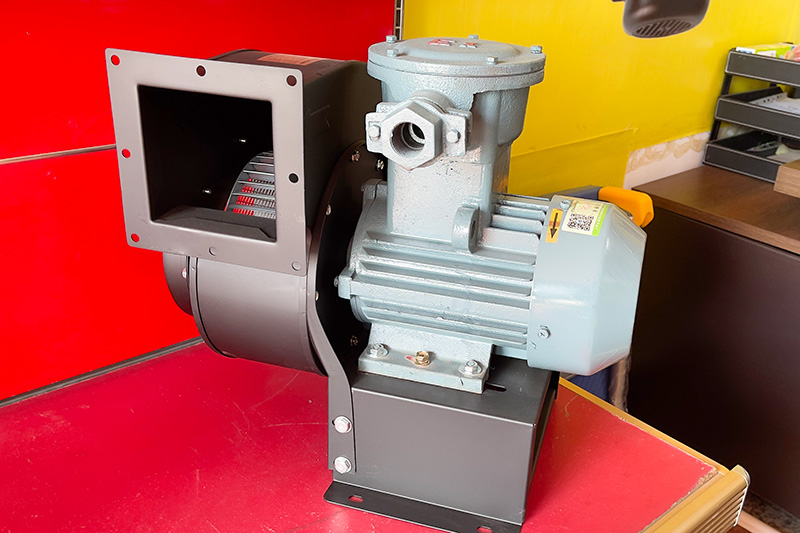

1. It is mainly composed of impeller, casing, air inlet, motor, connector, cooling wind blade and other components.

2. The impeller adopts multi-wing single centrifugal impeller, which is made of high-quality galvanized steel plate or cold-rolled steel plate, and the blades are designed according to the principle of aerodynamics. The impeller consists of 10 airfoil blades, curved front and rear discs. The material is made of high-quality steel plate, with high strength and good durability, and has been corrected by strict dynamic and static balance. Good air performance, high efficiency and smooth operation.

3. The converging inlet is used to simplify and save the vortex form, the gas flow loss is small, and the fan is high-temperature and high-efficiency.

4. Metal castings are used to connect with the motor. Cooling blades are installed on the shaft head of the motor, and water inlet and outlet pipes are installed on the outer wall of the metal casting to cool the metal castings and the shaft head to ensure the normal operation of the motor at high temperatures. temperature.

5. The motor adopts a special high-temperature motor, and the fluid part of the high-temperature fan adopts temperature-resistant materials, and the cooling structure has reliable performance. Compared with other boiler fans, the structure is simple, easy to maintain and cost-effective.

Installation and commissioning

Fan shaft installation

The thermal expansion of the main shaft of the high-temperature fan is realized through the axial movement of the bearing at the non-locating end. The thermal expansion of the main shaft under working conditions has been considered in the design, and the positioning dimensions of the bearing seat and impeller installation are generally clearly marked on the installation drawing. Issues to be paid attention to when carrying out on-site installation work:

(1) According to the expansion direction of the main shaft, the load end is selected as the positioning end;

(2) Determine the positioning and non-locating bearing seats according to the difference of the end cover.

system correction

The alignment of the system mainly includes: alignment of the center of the bearing seat, alignment of the fan shaft and the motor. In order to avoid "false alignment" in the hot state, the alignment of each part of the high temperature fan must be carried out at room temperature.

Installation of lubrication station

The installation of the fan lubrication station should not be too far away from the bearing seat, so as to avoid the high temperature environment. If the lubrication station is too far away, the oil inlet and oil return pipelines will be too long, the oil loss along the way will be large, and failures such as insufficient oil inlet pressure of the bearing seat, poor oil return, and oil leakage of the bearing seat will easily occur (especially when the car is started in a cold state in winter) most likely to occur).

Test machine

The medium density at room temperature is much larger than the actual working condition. Therefore, the cold-state test run of the high-temperature fan must ensure that the air inlet door is closed, otherwise it is easy to cause the current to be too high to start normally and cause damage to the hydraulic coupler when the load is started.

Diagnosis and Treatment of Common Faults

1. The vibration of the fan

Vibration exceeding the standard is the most common fault in the operation of the hot air blower, and it is an important factor affecting the safe operation of the fan and the normal production of the factory. There are many reasons for fan vibration, common reasons: rotor imbalance, poor system alignment, looseness, friction between moving and static parts, rolling bearing failure, rotor bending, resonance, fan vibration caused by motor failure, etc. Rotor imbalance is the most common cause of excessive fan vibration. The characteristics of pure rotor unbalanced vibration are obvious, and its performance: (1) the waveform is similar to a sine wave; (2) in the frequency spectrum, the harmonic energy is mainly concentrated in the fundamental frequency. Due to the special working environment of the process hot air blower in the sintering plant and the pelletizing plant, the factors leading to the imbalance of the fan rotor are also relatively complicated. Common causes and treatment methods of rotor imbalance of hot air blower in pelletizing plant.

2. High bearing temperature, high bearing temperature is also a common fault in the operation of hot air blowers. There are many reasons for it, but for high temperature fans, it mainly includes 6 aspects:

(1) The bearing wear is serious, and the axial and radial clearance is too large. This is mainly because the bearings have been used for too long, and the balls and cages are severely worn and need to be replaced;

(2) The amount of lubricating oil is insufficient or excessive. Most of the hot air blowers are lubricated by circulating oil. The oil pressure and oil temperature of the lubrication station have a great influence on the temperature of the bearing housing. Generally, the oil supply pressure of the thin oil station is 0.15-0.2MPa, and the oil supply temperature does not exceed 40°C. The oil filter should be cleaned regularly. At the same time, the oil inlet pipe and the oil return pipe should not be too close to the casing to avoid the radiation of the ambient temperature from affecting the oil temperature;

(3) The lubricating oil has deteriorated or the brand is wrong, and the viscosity is too low or too high. Generally, the lubricating oil of high-temperature fans is best replaced every six months.

(4) The ambient temperature is too high. The temperature of the bearing seat of the high-temperature fan fluctuates greatly with the ambient temperature, and the instability of the process operation leads to the instability of the air temperature, which affects the temperature of the bearing seat, which is a frequently encountered problem;

(5) Installation error. The bearing installation at both ends is not concentric or due to the error of the installation and positioning of the main shaft, the gap between the end cover of the non-locating end bearing seat and the outer ring of the bearing is too small. After the main shaft is heated and expanded, the friction between the outer ring of the bearing and the end cover will cause the bearing to heat up;

(6) The rotation of the outer ring of the bearing rubs against the inner hole of the bearing housing.