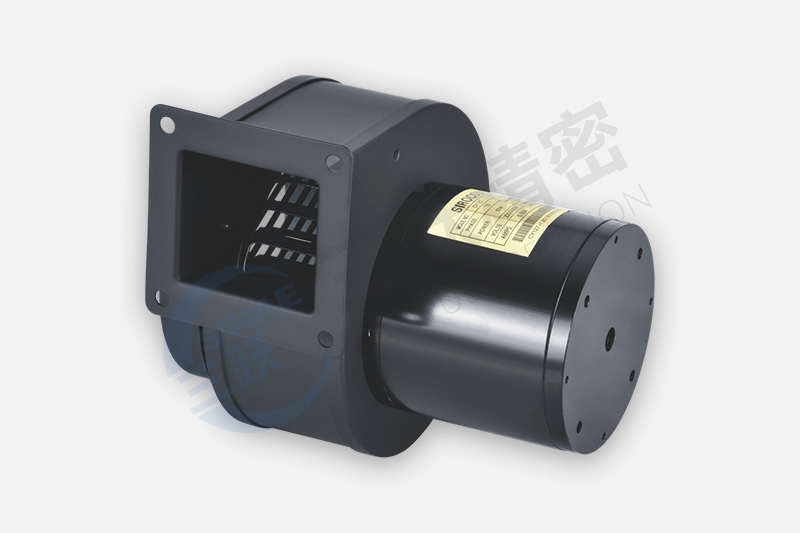

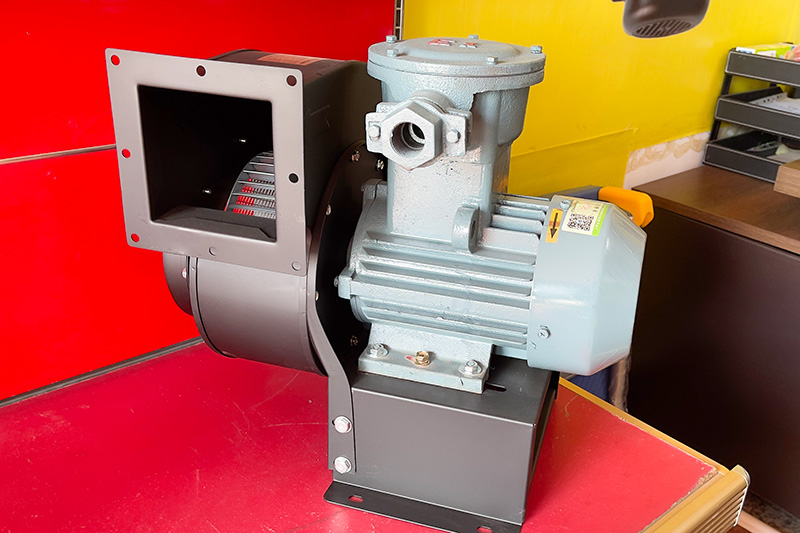

After the centrifugal fan has been used for a period of time, it needs to be repaired regularly. In order to reduce the damage of faults and ensure normal use, we need to do different levels of maintenance work. Due to the different maintenance time, when we use it, its maintenance cycle and maintenance The degree of maintenance is also different, so next we will give you a simple understanding of the relevant maintenance matters. Dongguan Sanyue Precision Electromechanical Co., Ltd. is a technology-based enterprise focusing on the research and development, manufacturing, sales and after-sales service of various specifications of centrifugal fans, centrifugal fans, duct fans, high-pressure blowers and other series of pneumatic products. Passed CE\FCC\ROHS and other certifications, contact number: +86-769-88811878.

1. Minor repairs:

Generally, it is necessary to disassemble the intake and exhaust pipes, clean the inside of the centrifugal fan casing, and check and adjust the rotor clearance. In addition, check the tightness of the belt or the wear of the coupling cancellation hole and the rubber ring, and replace the unqualified parts; check the oil quality and oil level, clean the oil mark, refuel or change the oil if necessary; check the shaft extension part. If the oil leaks, the seals should be repaired or replaced; check the tightening of each connecting bolt (including the anchor bolt), and tighten it in time if it is loose.

2. Middle repair:

Mainly disassemble the main and auxiliary oil tanks, check, repair and adjust the gear side clearance, clean, check or replace the bearings, clean the intake and exhaust pipes, check the condition of the intake and exhaust steam (such as whether the sound-absorbing material leaks), and purge the air filter Check, repair or replace electrical equipment, and check and repair other items listed in minor repairs item by item.

3. Overhaul:

That is, the disassembly inspection, which aims to restore the factory accuracy of the centrifugal fan. The content of the overhaul is mainly to replace the gears and bearings, and to check, adjust and restore the rotor clearance. In addition, matters such as seal repairs are included. In addition to other items listed in the mid-repair, it is also necessary to check whether the casing and wall panels are cracked or deformed, whether the radial runout of the rotor is out of tolerance, and whether there are defects such as blisters, cracks, wear or corrosion on the surface of the impeller. Then re-assemble, install and debug.

Generally, according to the degree of disassembly, the maintenance of centrifugal fans is divided into minor repairs, medium repairs and major repairs. It can be seen from this that the degree of disassembly determines the strength of the overhaul, whether it is an overall inspection or a partial inspection. This is very important. Under normal circumstances, we perform a small repair a week, a middle repair in a month, and a major repair in half a year to a year. , which should be under normal circumstances, so different situations should be analyzed in detail. Therefore, if you want the centrifugal fan to maintain a good use condition for a long time, it is necessary to do maintenance work and maintenance work, etc., so as to effectively delay the service life of the fan equipment and reduce the failure rate of the equipment.