When installing and using centrifugal fans in winter, special attention should be paid to the following points to ensure their safe, stable operation and extend their service life:

Installation precautions

Check the equipment environment

Ensure that there is no snow or water accumulation at the installation site to avoid adverse effects of moisture and low temperature on the equipment.When installing outdoors, rain and snow protection covers or protective measures should be installed.

Equipment inspection

Carefully check whether the fan and its components are damp, frozen or damaged during transportation and storage.

Check whether the fan bearings and rotors are flexible to ensure that there is no rust or jamming.

Electrical connection

In low temperature environments, cables and wiring need to use cold-resistant materials to prevent cable embrittlement or insulation damage.After installation, perform insulation tests, paying special attention to whether the motor insulation meets the standards.

Foundation stability

Ensure that the fan is installed on a flat and stable foundation to avoid vibration or tilting due to freezing and loosening of the foundation.Anti-vibration gaskets can be added during installation to reduce the impact of low temperatures on the smooth operation of the fan.

Lubrication inspection

Check the state of lubricating oil or grease to ensure that it still has good fluidity and lubrication performance in low temperature environment; replace it with low temperature resistant lubricant if necessary.

Precautions for use

Preheating and starting

The temperature is low in winter. The motor and fan should be preheated before starting to avoid thermal expansion and contraction of components due to excessive temperature difference.

Manually rotate the impeller before use to ensure that there is no jamming or icing.

Operation monitoring

After starting, closely observe the operation of the fan, including vibration, noise, current, voltage and other parameters to ensure the normal operation of the equipment.

Prevent condensation caused by low temperature from entering the motor or bearing.

Regular maintenance

Regularly clean the snow, frost and dust on the impeller, casing and air inlet and outlet to avoid affecting the efficiency of the fan.

After the winter operation, check the wear of the fan parts and perform maintenance in time.

Antifreeze measures

Take antifreeze measures for the air inlet and exhaust of the fan to prevent poor airflow or fan failure due to icing.

Maintenance during shutdown

When the fan is shut down for a long time, it should be properly stored in a dry and warm environment, and the impeller should be manually rotated regularly to prevent the bearing from rusting or the parts from getting stuck.

Special Tips

When operating centrifugal fans in winter, pay attention to the impact of ambient temperature on equipment materials and operating efficiency. If the temperature in the operating area of the equipment is extremely low (such as below -10℃), it is recommended to use a special model designed for low temperature environments or perform additional insulation treatment.

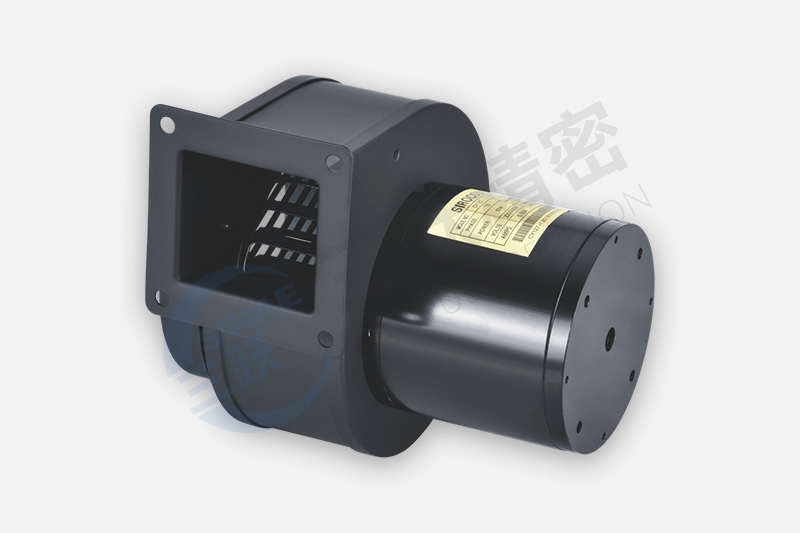

Dongguan Sanyue Precision Electromechanical Co., Ltd. is a technology-based enterprise focusing on the research and development, manufacturing, sales and after-sales service of a series of pneumatic products such as high-temperature centrifugal fans, high-temperature motors, long-axis motors of various specifications. Its products have passed multiple certifications such as CE\FCC\ROHS. Contact number: +86-139 2845 2905.